High Performance UAV

The High-Performance UAV project was focused on designing, constructing, and flying a fixed-wing uncrewed aerial vehicle (UAV). In addition, a ground station capable of receiving a live video and telemetry stream was constructed. Metrics of high performance included time aloft, maximum airspeed, distance flown, and adherence to the designed flight plan. The efforts of the High-Performance UAV team were very closely aligned with those pervading the aerospace industry, creating more sustainable, efficient, and environmentally sound air transportation methods.

Design Process

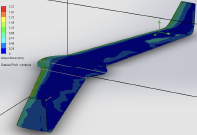

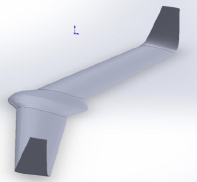

Much of the final design of the UAV was done using SolidWorks. In this way, flow simulations were performed in order to verify lift and drag forces and determine the aerodynamic center and approximate center of mass of the final vehicle. This verification was crucial to ensuring the aircraft would leave the ground.

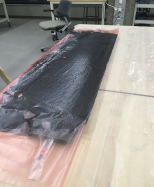

The UAV was constructed by first cutting a 3D “mold” from XPS foam using a ShopBot CNC router, an additional bonus of the aforementioned Solidworks model of the vehicle. Since the ShopBot could only cut on one side of the foam, the two wings and fuselage had to be split into “top” and “bottom” components which were later glued together to form the final mold. A carbon fiber layup was done on top of these three components to form the final airframe. Such a layup yielded a remarkably strong yet exceptionally light airframe. The final airframe with a wingspan of approximately eight feet (2.4 m) weighed under six pounds (2.7 kg).

The roll, pitch, and yaw of vehicle were controlled via differential spoilers. Such a design was chosen for use with the flying wing, as they provided a fairly simple yaw mechanism without the need for vertical control surfaces.

Thrust was provided via electric ducted fans as the duct reduced significant losses in thrust from the tips of traditional propellers. In addition, retractable landing gear was used to further reduce drag experienced in flight.

The electronics, including video and data transmitters, autopilot computer, GPS receiver, airspeed sensor, and batteries were mounted in the center of the fuselage. A camera protruded slightly from the bottom of the vehicle in order to stream live in-flight video to the ground station.

The autopilot computer was a store-bought Navio+, chosen for its versatility as well as convenience, as the project was only funded for a single academic year. A manual override was present, allowing for someone on the ground with a remote controller to take control should a problem with the flight computer occur.

The High-Performance UAV project proved an extraordinary opportunity to hone design and construction skills, while gaining massive exposure to the intricacies associated with designing an aircraft from scratch. In addition, the construction techniques used throughout the project verified the capability of undergraduates to design and build a completely customized airframe.